When your home’s Boiler a sealed vessel that heats water for your radiators or hot‑water taps stops delivering warmth, it’s hard to know whether it’s just a glitch or a full‑blown failure. This guide walks you through the most common clues, quick DIY tests, and safety rules so you can decide if a simple reset will do or if a professional call is unavoidable.

Key Signs Your Boiler Might Be Broken

- No heat coming out of radiators or under‑floor loops, even though the thermostat is set high.

- Unusual noises - banging, whistling, or rapid clicking - that weren’t there before.

- Water leaking from the pipework, the pressure relief valve, or the boiler’s casing.

- Cold‑water supply from taps that should be hot, especially in the morning.

- Repeated boiler shut‑offs with error codes flashing on the display.

- Foul smell of gas or a persistent yellow‑orange flame that looks weak.

Each symptom points to a specific component, and spotting them early can save you from a costly repair.

How to Perform Basic Checks Before You Call a Pro

- Verify power and fuel supply. Ensure the electricity socket or circuit breaker is on, and for gas‑fired units confirm that the gas valve is fully open. A tripped breaker or closed valve mimics a broken boiler.

- Inspect the Thermostat. Set it a few degrees higher than room temperature. If the display reads correctly but the boiler never fires, the thermostat may be faulty or mis‑wired.

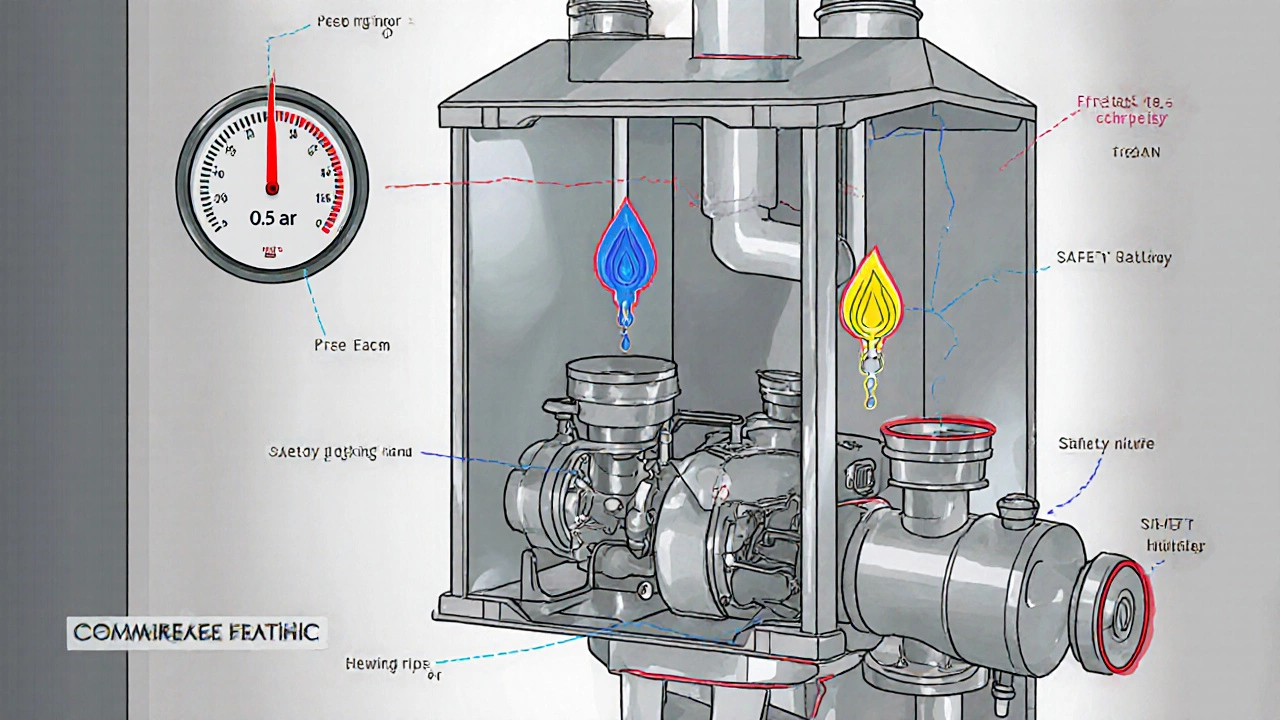

- Check the pressure gauge. Most residential boilers operate between 1 and 1.5 bar when cold. If the needle sits below 0.5 bar, the system is under‑pressurised and will lock out to prevent damage.

- Look at the Pilot light or electronic ignition. A blue, steady flame indicates proper combustion. A yellow or flickering flame signals incomplete burning, which can trigger safety shutdowns.

- Read error codes. Modern boilers display alphanumeric codes. Write down the code and consult the manufacturer’s manual - most manuals are available online - to pinpoint the affected part.

- Listen for the Burner sound. A clean burner produces a low hum. A sputtering or clanking noise means debris or air in the combustion chamber.

If all of the above look normal yet you still have no heat, the fault is likely deeper inside the system.

Understanding Common Faulty Parts

Below is a quick rundown of the most failure‑prone components and what each symptom usually means.

- Heat exchanger: Builds up limescale or corrosion over time. A blocked exchanger reduces water temperature and can cause the boiler to overheat and shut down.

- Expansion tank: Holds extra water to absorb pressure changes. If the bladder ruptures, the system loses pressure quickly, triggering a low‑pressure lockout.

- Safety valve: Releases excess pressure. A stuck valve can leak water or cause the boiler to stop heating as a precaution.

- Circulator pump: Moves hot water through radiators. A humming pump that suddenly stops often signals a seized motor.

- Gas valve: Controls gas flow to the burner. A faulty valve may stay closed despite a call for heat, leaving the boiler dead.

- Electrical heating element (in electric boilers): Burns out after many heating cycles, leaving the system without hot water.

Knowing which part aligns with which symptom helps you describe the issue accurately to a service engineer, potentially speeding up the repair.

When to Call a Professional

Even the most handy homeowner should hand over the job when any of these red flags appear:

- Smell of gas - immediately turn off the gas supply and ventilate the area.

- Continuous error codes after resetting the boiler.

- Water pooling around the boiler that doesn’t stop after a short period.

- Repeated boiler lockouts despite correcting pressure and thermostat settings.

- Any repair involving the internal combustion chamber, heat exchanger, or gas valve - these require specialist tools and certification.

Professional technicians can also perform a thorough flushing of the system, which removes scale that DIY chemicals often miss.

DIY Safety Tips

- Always turn off power and close the gas supply before opening panels.

- Wear insulated gloves and safety glasses when handling hot water or metal parts.

- Never attempt to replace a pressure relief valve yourself; it’s a critical safety device.

- Keep a fire extinguisher rated for Class B (flammable liquids) nearby when working with gas appliances.

- After any repair, run the boiler through a full cycle and watch for leaks before resuming normal use.

Quick Diagnostic Checklist

| Symptom | Probable Cause | First Action |

|---|---|---|

| No heat at all | Thermostat or gas valve closed | Check thermostat setting; open gas valve |

| Low pressure reading | Expansion tank failure or leak | Inspect for visible leaks; top‑up pressure |

| Clicking noise, short‑run cycles | Air trapped in system or faulty pump | Bleed radiators; listen to pump |

| Water on floor near boiler | Leaking safety valve or heat exchanger | Turn off boiler, call professional |

| Yellow flame or smell of gas | Pilot light issues or delayed ignition | Reset pilot, check for drafts |

Frequently Asked Questions

Why does my boiler keep shutting off?

Most modern boilers have safety cut‑outs that trigger when pressure is too low, temperature spikes, or a flame fails to ignite. Check the pressure gauge, make sure the thermostat is calling for heat, and look for any error codes that point to the burner or gas valve.

Can I reset a boiler myself?

Yes, most units have a reset button behind the front panel. Turn the boiler off, wait 30 seconds, and press reset. If the problem recurs, it’s a sign of an underlying fault that needs professional attention.

What does a flashing ‘E’ code mean?

‘E’ followed by numbers is a manufacturer‑specific error. For example, E01 on many UK models indicates a pressure‑sensor fault, while E02 points to an ignition failure. Look up the code in the user manual or on the maker’s website for exact meaning.

Is it safe to use the boiler after a minor leak?

No. Even a small leak can lower system pressure and cause the boiler to shut down. Turn the unit off, dry the area, and call a qualified engineer to assess the source before restarting.

How often should I have my boiler serviced?

A yearly service is the industry standard. An annual check clears sludge, inspects the heat exchanger, calibrates safety devices, and keeps the warranty valid.