Extractor Fan Performance Tester

Test Results

Click "Test Fan Performance" to analyze your extractor fan's condition.

When the kitchen or bathroom smells like stale air, the first place to look is the extractor fan - a device that pulls moist or odorous air out of a room and vents it outside. A fan that’s not moving enough air, making strange noises, or refusing to turn on can leave you with lingering smells, excess humidity, and even mold growth. Below is a step‑by‑step extractor fan test you can run with basic tools, so you’ll know exactly what’s wrong before you call a professional.

Why a Proper Check Matters

Running an extractor fan isn’t just about comfort; it protects the building envelope. According to a 2023 NewZealand Building Survey, homes with poorly ventilated kitchens see 30% higher humidity levels, which accelerates timber rot. Knowing how to verify fan performance helps you keep indoor air quality high and avoid costly repairs down the line.

Job 1: Confirm Power Supply

The simplest reason a fan won’t run is a missing electrical connection. Follow these three checks:

- Locate the circuit breaker for the fan. In most Auckland homes it sits in the main panel labeled “kitchen fan” or “bathroom extractor.” Flip it off, wait a few seconds, then flip it back on.

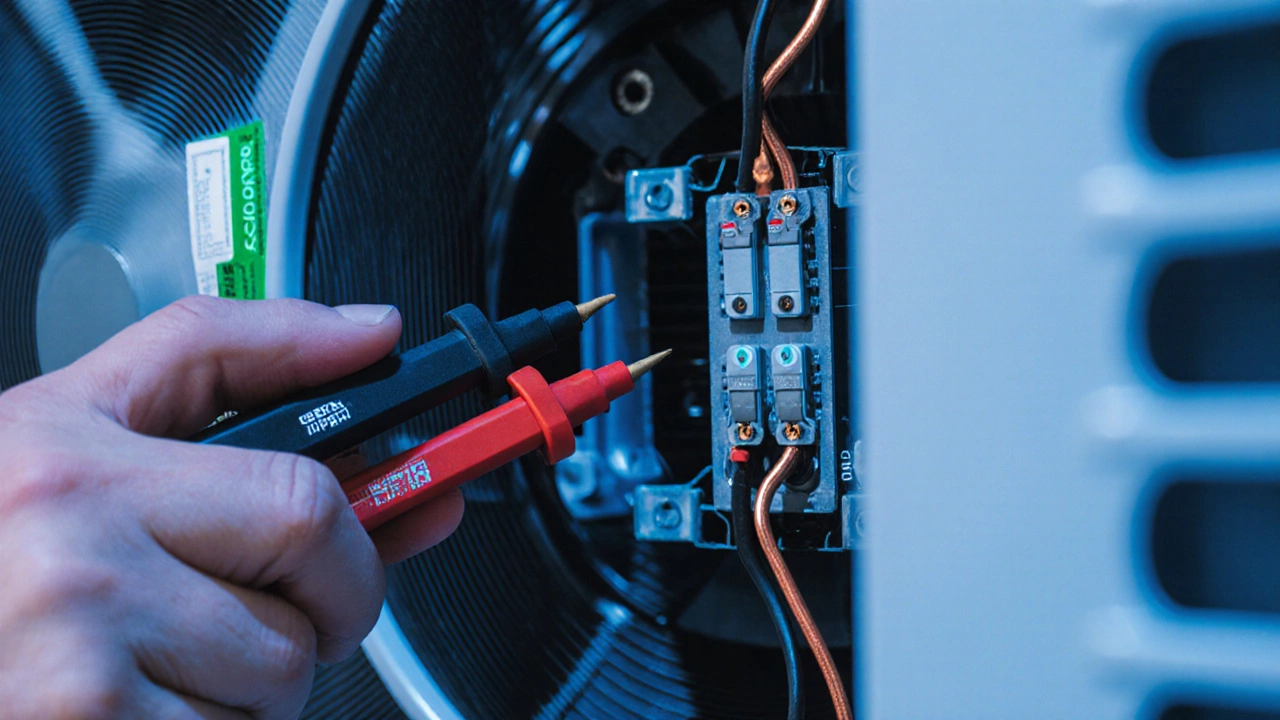

- Use a multimeter set to AC voltage. Touch the probes to the fan’s live and neutral terminals (usually found behind the grill). You should read between 220V and 240V in NewZealand.

- If you get 0V, the breaker may be tripped or the wiring damaged.

- If you read voltage but the fan is silent, the motor is likely the culprit.

- Check the wall switch. A faulty switch can mimic a dead fan. Bypass it by directly applying 220V to the fan terminals - only do this if you’re comfortable working with live wires.

- If the fan spins when bypassed, replace the switch.

Job 2: Listen for Motor Activity

Even if power is present, a motor may be stuck. Turn the fan on and stand close (but safe distance) to hear any hum.

- A faint hum without airflow usually means the motor’s start capacitor has failed.

- A high‑pitched squeal can indicate worn bearings.

- No sound at all points to a burned‑out motor windings.

When you hear any noise, note it - it’s useful information for a technician.

Job 3: Measure Airflow (CFM)

Airflow is the true measure of fan health. The standard unit is cubic feet per minute (CFM). An indoor air quality specialist recommends at least 100CFM for a typical kitchen extractor.

To check:

- Grab an anemometer - a handheld device that measures wind speed. If you don’t own one, a piece of lightweight paper can give a rough idea: hold it in front of the vent; if it flutters vigorously, airflow is decent.

- Place the anemometer’s sensor at the centre of the vent opening, pointing downstream.

- Read the velocity in meters per second (m/s). Multiply by the vent’s cross‑sectional area (in square meters) and then by 2118 to convert to CFM.

- Example: Vent diameter 0.2m → area ≈ 0.031m². Velocity 5m/s → 5×0.031×2118 ≈ 328CFM, which is excellent for a kitchen.

- If the result is well below the fan’s rated CFM (often printed on the fan’s motor housing), you have an airflow restriction - dirty filters, clogged ducts, or a failing motor.

Job 4: Inspect Physical Condition

Physical wear can reduce performance. Remove the outer grill (usually clipped or screwed) and look for these signs:

- Accumulated grease or dust - clean with a soft brush and mild detergent.

- Corroded motor housing - scrape off rust, then coat with a high‑temperature spray paint.

- Loose wiring connections - tighten terminal screws, but ensure power is off.

- Worn fan blades - if blades are warped, replace them; they can cause imbalance and noise.

Job 5: Assess Ductwork Health

Even a perfect fan can be throttled by obstructed ducts. Follow these quick checks:

- Feel the outside vent when the fan runs. If you barely feel any air, the duct may be blocked by nests or debris.

- Inspect the interior duct line (if accessible) for crushed sections or sharp bends that increase static pressure.

- Consider installing a backdraft damper if you notice reverse airflow on windy days - it can reduce fan efficiency.

Job 6: Verify Noise Level (Decibels)

A healthy extractor typically runs between 40dB and 55dB. If you have a smartphone decibel app, measure the sound 1m from the vent:

- Above 60dB suggests motor wear or duct resonance.

- Below 30dB may indicate the fan is under‑performing - it could be a sign the motor is slipping.

Quick Troubleshooting Checklist

| Symptom | Likely Cause | Simple Fix |

|---|---|---|

| No power | Tripped breaker or unplugged unit | Reset breaker, check plug |

| Humming but no airflow | Motor capacitor failure | Replace capacitor (NZ$25‑30) |

| Weak airflow (<100CFM) | Clogged filter or duct | Clean/replace filter, clear duct |

| Strange squeal | Worn bearings | Lubricate or replace motor |

| Excessive noise (>60dB) | Loose blades or backdraft | Secure blades, install damper |

When to Call a Professional

If you’ve run through the above steps and the fan still under‑performs, it’s time to call a qualified technician. Look for these red flags:

- Burnt smell from the motor housing.

- Electric arc or visible sparks.

- Repeated breaker trips despite a new capacitor.

Professional repair in Auckland averages NZ$120‑150 for labor, plus parts. Knowing the exact fault (e.g., “motor capacitor”) can shave off diagnostic fees.

Maintenance Tips to Keep Your Fan Happy

Regular care prevents most problems:

- Clean the grill and filter every 3‑4months.

- Run the fan for a minute after cooking to clear steam.

- Inspect duct ends yearly for bird nests or leaves.

- Schedule a professional service every 2‑3years if the fan is over 10years old.

Frequently Asked Questions

Why does my kitchen extractor fan run but not move any air?

Most often the motor’s start capacitor has failed, allowing the motor to spin without enough torque to push air. Replacing the capacitor restores normal airflow.

Can I use a regular household vacuum to test fan airflow?

A vacuum can give a rough sense of suction but cannot provide a reliable CFM reading. An anemometer or a calibrated airflow meter is the preferred tool for accurate measurement.

My extractor fan makes a high‑pitched squeal - is that dangerous?

The squeal usually signals worn bearings or a misaligned motor shaft. It’s not immediately hazardous, but continued operation can damage the motor and should be fixed soon.

How often should I replace the filter in an extractor fan?

For most kitchen fans, a cleanable aluminium mesh filter lasts 3‑4months with regular cooking. Charcoal or carbon filters in bathroom units typically need replacement every 6‑12months.

Is it normal for an extractor fan to run louder at higher speeds?

Yes, sound level rises with speed because the motor works harder and more air turbulence is created. However, a sudden jump of >10dB usually means something is wrong, such as a loose blade.