Extractor Fan Maintenance Calculator

Calculate your next maintenance

Based on your kitchen usage patterns and fan type

If your kitchen extractor fan has suddenly gone quiet, you know how frustrating it is. Smoke lingers, grease builds up, and the air feels thick - all because a simple device you barely notice stopped doing its job. It’s not magic. It’s not bad luck. It’s usually one of five common problems that kill these fans long before they should die.

The Motor Has Given Out

The motor is the heart of your extractor fan. Most models run for 8 to 12 years before the motor wears out. If you hear a low hum but no airflow, or if the fan spins slowly and then stops, the motor is likely failing. Older fans with brushed motors are especially prone to this. Carbon brushes wear down over time, breaking the electrical connection. You won’t see it, but you’ll feel it - the fan struggles to start, then cuts out.

Some people try to fix it by tapping the fan housing. That might get it spinning for a few seconds, but it’s just delaying the inevitable. Motors don’t heal. If the motor’s dead, replacing it is cheaper than buying a whole new unit - unless your fan is over 10 years old. In that case, upgrading to a modern, energy-efficient model makes more sense.

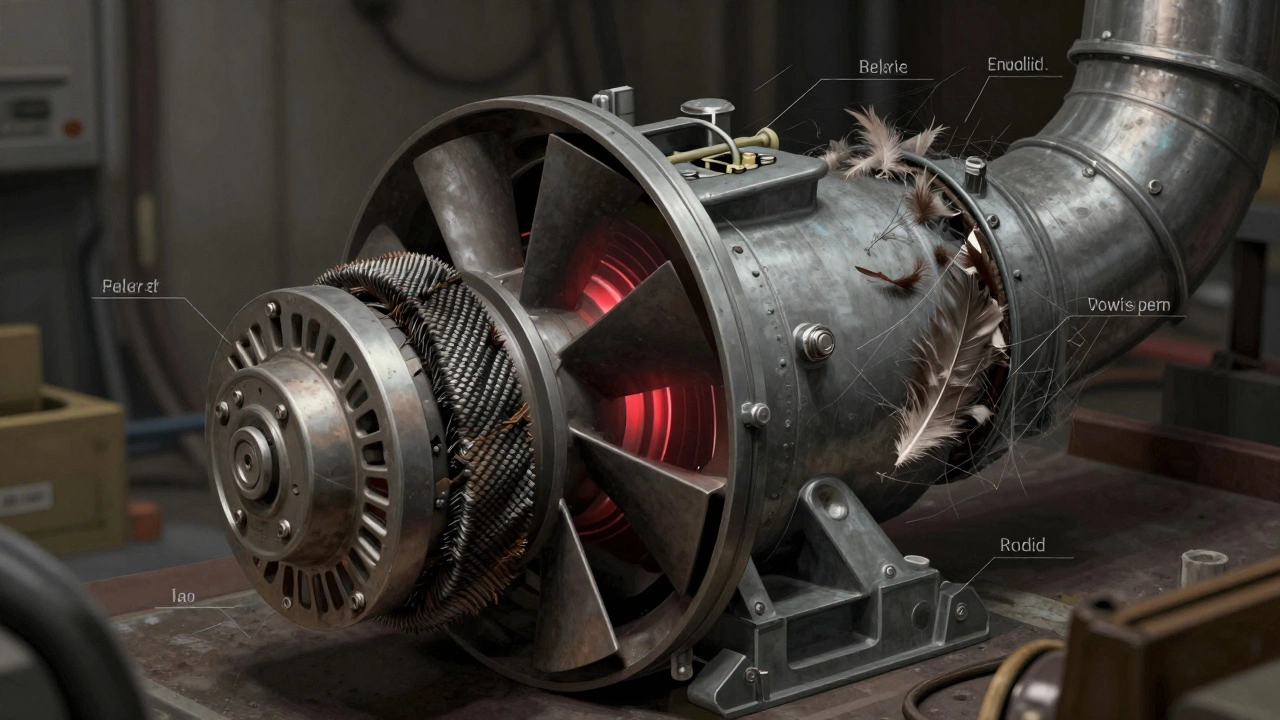

Grease and Dirt Have Clogged Everything

This is the #1 reason extractor fans stop working - and it’s also the easiest to fix. Grease, steam, and cooking particles build up inside the fan housing, on the blades, and in the ductwork. Over time, that gunk turns into a sticky, hardened paste. It slows the blades down, forces the motor to work harder, and eventually causes it to overheat and shut off.

Check the grease filter first. If it’s dark brown or black, and you can’t see the metal mesh underneath, it’s clogged. Remove it, soak it in hot soapy water for 30 minutes, then scrub with a brush. If it’s disposable, replace it. Next, wipe down the fan blades with a degreaser. Don’t just spray - wipe. Grease doesn’t evaporate. It clings.

Many people forget the duct. If your fan vents to the outside, check the external hood or cap. Birds, leaves, and spider webs can block airflow. A clogged duct doesn’t just reduce performance - it forces the motor to burn out faster. Clean the duct at least once a year. Use a vacuum with a long nozzle or a flexible brush designed for chimney cleaning.

The Wiring or Switch Is Faulty

If the fan doesn’t turn on at all - no hum, no light - the problem might be electrical. The wall switch could be worn out. The wiring behind the fan might be loose. Or the internal capacitor (a small component that helps the motor start) has failed.

Before you touch anything, turn off the power at the breaker. Then remove the fan cover and check the wires. Look for frayed insulation, burnt spots, or loose terminals. If the wires are secure, test the switch with a multimeter. A good switch should show continuity when turned on. If it doesn’t, replace it. Capacitors are trickier. They look like small silver cylinders. If they’re bulging or leaking, they’re dead. Replacing one costs under $10 and takes 15 minutes.

Don’t guess. If you’re not comfortable working with electricity, call a professional. A faulty connection can overheat and cause a fire.

The Fan Is Overloaded or Poorly Installed

Some extractor fans are too small for the kitchen. A 100 CFM fan won’t keep up in a large open-plan kitchen with a gas range. Others are installed wrong - ducts that are too long, too many bends, or made of flexible plastic that collapses. These issues force the fan to run constantly at full power, burning out the motor in 2-3 years instead of 10.

Check the fan’s rating. It should move at least 100 CFM for a small kitchen, and 150-200 CFM for a large or commercial-style setup. If your duct runs more than 10 feet or has more than two 90-degree bends, airflow drops by 30% or more. That’s like trying to breathe through a straw. Replace the duct with rigid metal, shorten the run, or upgrade the fan.

Also, don’t use a range hood fan as a bathroom exhaust. They’re not designed for constant moisture. Humidity eats away at bearings and wiring. Use the right tool for the job.

It’s Just Old - And Not Worth Fixing

Most extractor fans last 10 to 15 years. If yours is 15 or older, and it’s started acting up, it’s probably time to replace it. New models are quieter, more efficient, and come with features like automatic timers, humidity sensors, and LED lighting. A $150 fan today will use half the electricity of a 20-year-old model and last twice as long.

Older fans often use parts that are no longer made. Finding a replacement motor or capacitor can take weeks - if you can find it at all. And even if you do, the rest of the unit is likely worn out. You’re paying for a temporary fix.

Look for fans with sealed bearings, washable filters, and easy-access motors. Brands like Bora, Falmec, and Extracto offer reliable models with 5-year warranties. Don’t go for the cheapest option. The cost difference between a $70 and a $200 fan is less than the price of one professional repair.

What to Do Next

Start simple. Turn off the power. Remove the grease filter. Clean it. Turn the fan back on. If it works, you found the problem. If not, check the switch and wiring. If you’re unsure, don’t risk it. Electricity and grease don’t mix safely.

Keep a log. Note when the fan started acting up, what you did to fix it, and how long it lasted. That helps you spot patterns. If it keeps failing after repairs, the issue isn’t the fan - it’s the setup.

Most extractor fans fail because of neglect, not bad design. Clean it twice a year. Don’t let grease build up. Don’t ignore strange noises. A little maintenance saves you hundreds.

Why does my extractor fan make a grinding noise?

A grinding noise usually means the motor bearings are worn out or grease has hardened around the shaft. If the fan is over 8 years old, the bearings are likely beyond repair. Cleaning won’t fix it - you need a new motor or a new fan. If the noise started after you cleaned the fan, you may have over-tightened the blades or damaged the motor mount.

Can I use my extractor fan if the light is broken?

Yes, the light and fan are usually on separate circuits. A dead bulb won’t stop the fan from working. But if the fan also stopped working at the same time, the issue is likely the wiring or control board. Check the power connection to the fan unit, not just the bulb.

Why does my extractor fan turn on by itself?

This happens with models that have a humidity sensor. If the sensor is dirty or faulty, it can misread steam as high humidity and turn on automatically. Clean the sensor with a dry cloth. If it keeps happening, the sensor may need replacing. Some fans also have timers that activate after cooking - check your manual to see if this is a feature.

Should I replace the duct when I replace the fan?

Always. Flexible plastic or foil ducts collapse, trap grease, and reduce airflow by up to 50%. Rigid metal ducts last longer, are easier to clean, and improve efficiency. If your duct is older than 10 years, or has visible sagging, bends, or damage, replace it. It’s not optional - it’s part of the job.

Is it safe to run the extractor fan without a filter?

No. Running the fan without a grease filter lets oil and particles enter the motor and duct. This causes buildup inside the housing, leading to overheating and motor failure. Even a dirty filter is better than no filter. Replace or clean the filter before using the fan again.

Final Tip: Don’t Wait for Failure

Extractor fans don’t die suddenly. They whisper warnings first. A slight vibration. A faint buzzing. Smoke that lingers longer than usual. These aren’t normal. They’re signs. Clean your fan every six months. Check the duct once a year. Replace the filter when it looks like charcoal. Small habits prevent big repairs - and big bills.